As early as the 1990s, some biodegradable plastic products have already appeared on the market in China. Take the packaging material plastic bag as an example, then the market is commonly used polyethylene (PE) material, but because there is no strong policy support, and the high cost of artificial degradation (need ultraviolet, ozone, thermal oxidation, photo-oxidation and other processing technology), the use of coverage is not wide. In recent years, environmental protection has become a global concern, and China has also introduced a series of policies such as "plastic restriction", both policy support and technological development, biodegradable products are used in large quantities in today's society.

▲ Biodegradable packaging already in common use

Nowadays, more and more customers and consumers are consulting degradable plastic bags, according to Rocktec's senior application engineer, in fact, degradation can be divided into "degradable" and "fully degradable".

Degradable refers to the plastic production process to add a certain amount of additives (such as starch, modified starch or other cellulose, photosensitizers, biodegradable agents, etc.), that is, PE + degradation agent; or add starch, stone powder, so that its stability is reduced, easier to degrade in the natural environment. This kind of plastic products can be degraded, but not completely. In addition, certain degraders themselves have certain environmental pollution hazards, which is also one of the reasons why we should fully promote fully degradable plastics.

Since the above-mentioned degradable products are mainly petroleum-based products, they are decomposed by chemical reaction rather than microbial organic decomposition. Therefore, they do not decompose completely into organic matter, but rather into tiny pieces that enter the environment, resulting in so-called microplastics (<5 mm in diameter) pollution. These microplastics are ingested by animals into the food chain and can eventually return to human society through the biosphere causing major problems.

Of course, requiring plastic products to be fully degradable is relatively more technically demanding and costly.

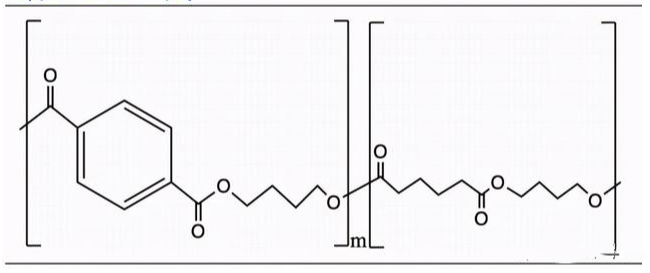

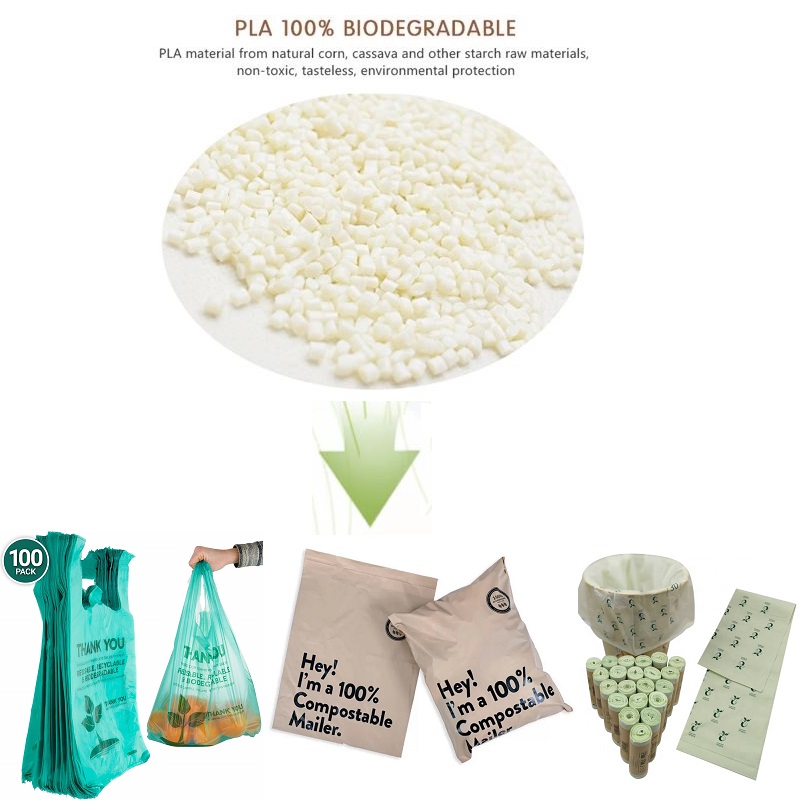

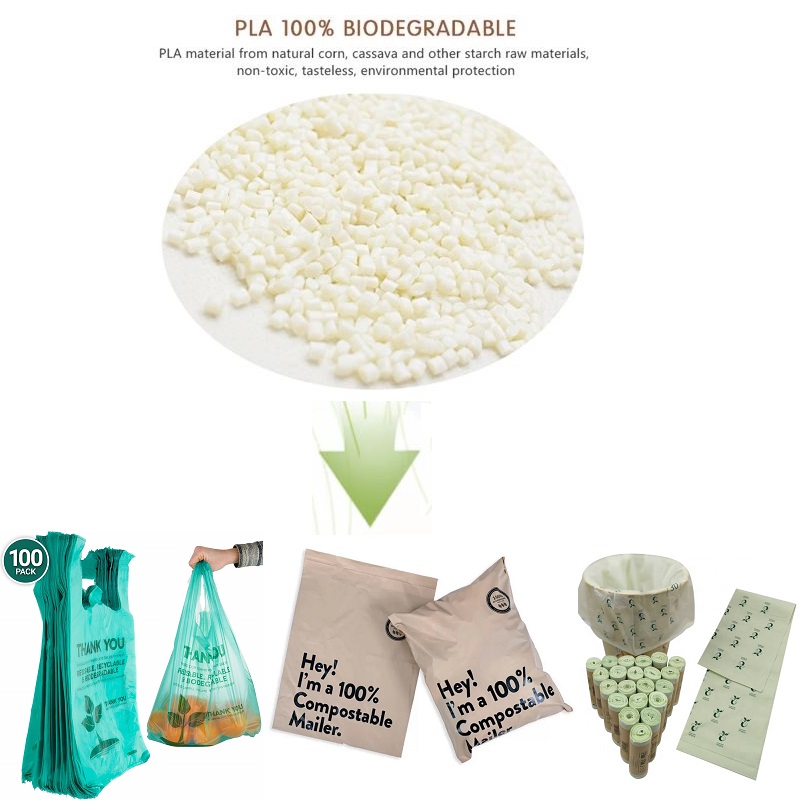

The current fully degradable products are mainly made of PBAT + PLA (polyhexanedioic acid/butylene terephthalate + polylactic acid) without PE material, and are fully degradable! It means that all plastic packaging bags are degraded into water and carbon dioxide. The main source of this fully degradable material is made from corn, cassava, etc., which is processed into lactic acid, also known as PLA.

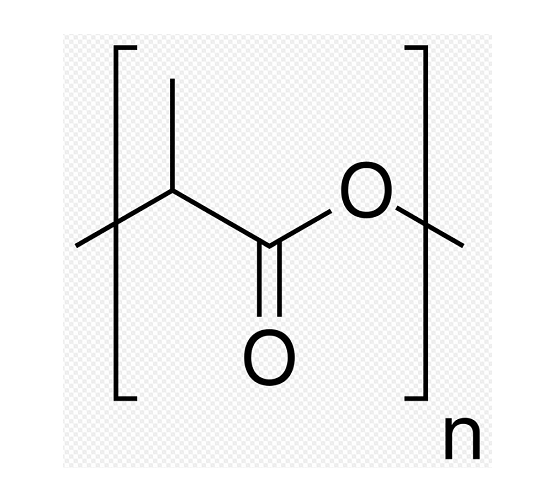

Polylactic acid (PLA) is a new type of biological substrate and renewable biodegradable material, starch raw materials through saccharification to get glucose, and then fermentation from glucose and certain strains of bacteria to make high-purity lactic acid, and then through chemical synthesis method to synthesize a certain molecular weight of PLA. It has good biodegradability and can be completely degraded by microorganisms in nature under specific conditions after use, which eventually generates carbon dioxide and water and does not pollute the environment, which is very beneficial to protect the environment and is an environmentally friendly material for workers.

At present, the main bio-based material of fully degradable bags consists of PLA+PBAT, which can be completely decomposed into water and carbon dioxide in 3-6 months under composting condition (60-70 degrees), without pollution to the environment.

It may be easier to understand further if we look at this issue from the point of view of the chemical structure of the material. According to a 2015 study by Berit Gewert's team at the School of Environmental Sciences and Analytical Chemistry, Stockholm University, Sweden, on the degradation pathway for degradation of plastic polymers floating in the marine environment (Pathway for degradation of plastic polymers in the marine environment. Environ. Sci.: Process Impacts, 2015, 17, 1513-1521), the chemical structure of plastic products is classified into two main categories: those with a "carbon-carbon skeleton" and those with a "heteroatomic skeleton". "two types of materials.

PE polyethylene, for example, is a polymer plastic with a carbon-carbon backbone. Since the entire main chain is carbon atoms, the charge distribution outside the nucleus is relatively uniform and it is not easily broken by other nucleophilic chemicals, such as acids and bases. Therefore, the chemical stability is relatively high and not easily degraded in a short period of time, and can only be promoted by means of high-energy ultraviolet light and high-temperature oxidation.

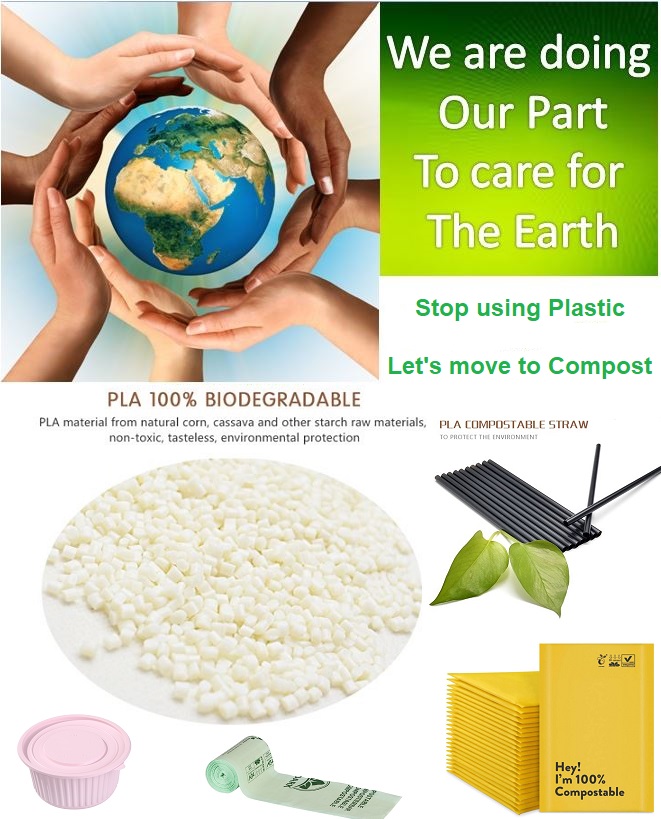

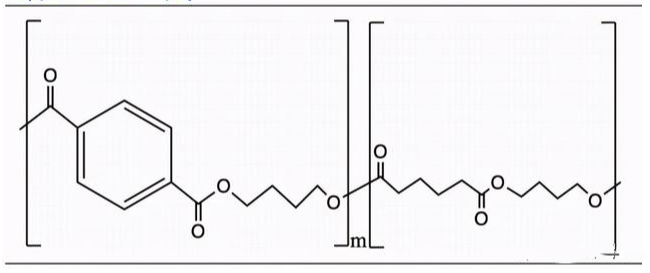

As for the above talked about fully degradable plastics PLA+PBAT, their main chain structures all contain carbon-oxygen heteroatom structures, and their atomic extra-nuclear charges will be unevenly distributed due to polarization, resulting in their being more easily broken into small molecules by the attack of other nucleophilic chemicals, and thus further degraded completely by microorganisms.

PBAT, poly(adipic acid)/butylene terephthalate

PLA, poly(lactic acid)

In addition, the use of this heteroatomic skeleton structure of plastic products has an additional benefit is that, because the heteroatomic bonding energy than the carbon-carbon bonding energy, so the material's heat resistance is better, no more PE plastic bags (temperature resistance of about 70 ℃) by the embarrassment of food scalding.

Since there are so many benefits of plastic degradation, it is especially important to be able to conduct plastic degradation tests for qualification.

For biodegradation

, Fuzhou Xinchuang BIO-TECHNOLOGY Co., Ltd. can provide

Compostable Bag/Compostable Tableware/Compostable Cup/Compostable Film/Compostable Adhesive Tape。etc., in accordance with relevant domestic international standards. After many times of practice, it is proved that degradable plastic products can achieve complete degradation.

Deutsch

Deutsch русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의

SUPPORT 24/7

SUPPORT 24/7 BUSINESS QUIRY

BUSINESS QUIRY Our ADDRESS

Our ADDRESS  Leave A Message

Leave A Message

IPv6 network supported

IPv6 network supported