Degradable And Compostable Plastic Raw Material Starch Resin Blown Film

Feature:

1. Suitable for 100% biodegradable packaging bags, including shopping bags, garbage bags, zipper bags, pet feces bags, electronic product packaging, food packaging bags, etc.;

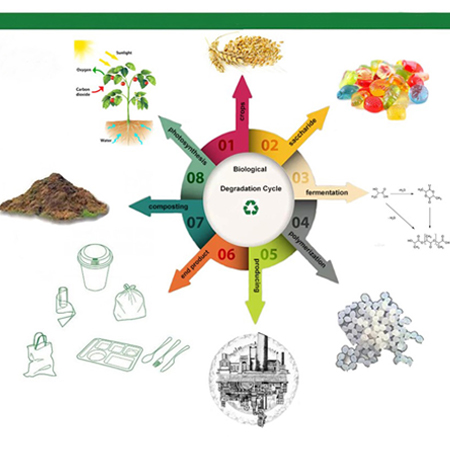

2. Environmental protection, plant-based ingredients, non-toxic and pollution-free;

3. The products produced have no chemical pungent smell and have a light plant fragrance;

4. It can be adapted to various plastic forming processes.

Product Display:

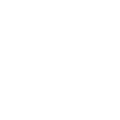

Production Process:

Our Advantages:

1. No pungent odor, with light fragrance of plants;

2. Biodegradable and compostable;

3. PBAT, PLA, modified starch components reduce pollution and protect the environment

4. Applicable to all kinds of plastic processing equipment, can make garbage bags, packaging bags, shopping bags, pet poop bags, etc.

Ordering Product:

|

Item:

|

GCBM0103

|

|

Product Name:

|

Eco-friendly Biodegradable PLA resin

|

|

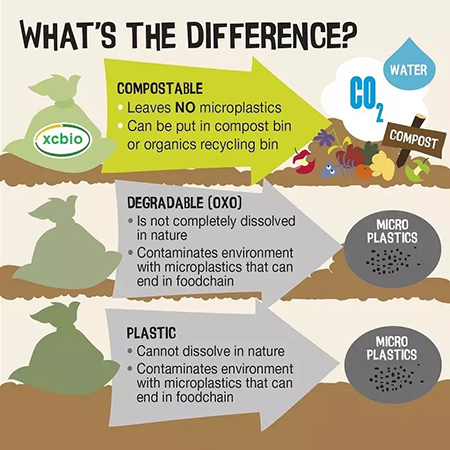

Component:

|

PBAT, PLA, CaCO3

|

|

Packaging:

|

25kg/bag

|

|

Color:

|

White

|

|

Features:

|

1. 100% biodegradable and compostable.

2. Compared to the traditional plastic ,save over 25% petrochemical resource.

3. Compared to the traditional plastic, reducing over 40% CO2 emissions.

|

|

Certification:

|

DIN CERTO/ ASTM D 6400/DIN EN 13432/OK COMPOST

|

|

MOQ:

|

25 kg

|

|

Price term:

|

FOB any port of China,The price offer based on final sample quality and design

|

|

Delivery time:

|

depend on which transportation you choose

|

|

Shipment:

|

By Sea/ AIR/ Train/Express .ect

|

|

Payment term:

|

T/T,L/C, Sample charge accept PAYPAL

|

T/T: 50% of deposit by T/T, 50% for balance should be

paid before shipment or upon B/L copy.

If the order is less than 3000 USD, 100% T/T should be paid.

|

Technical Report:

TECHNICAL DATA SHEET OF GCBM0103

GCBM0103 (PBAT/ Modified starch Resin For Film)

Component: PBAT, PLA, CaCO3

Appearance: white resin

Features:

1. 100% biodegradable and compostable.

2. Compared to the traditional plastic ,save over 25% petrochemical resource,

3. Compared to the traditional plastic, reducing over 40% co2 emissions.

4. No phthalate, no bisphenol A, non-toxic and pollution-free.

5. Have excellent mechanical properties ,could be applied to general plastic processing facilities for various molding processing.

Application: 100% biodegradable packing bags, including shopping bag, rubbish bag, zipper bag, pet excrement bag, package for electronic product.

GCBM0103 (PBAT/ Modified CaCO3 Resin For Film):

|

Biodegradable waste bags

|

|

Properties

|

ASTM

|

Test Condition

|

S.I. Units

|

Typical Values

|

|

Mechanical

|

|

Tensile Strength(Longitudinal)

|

ASTMD 4321-2004

|

50mm/min

|

Mpa

|

≥17

|

|

Tensile Strength(transverse)

|

ASTMD 4321-2004

|

50mm/min

|

Mpa

|

≥16

|

|

Elongation(Longitudinal)

|

ASTMD 4321-2004

|

50mm/min

|

%

|

≥200

|

|

Elongation(transverse)

|

ASTMD 4321-2004

|

50mm/min

|

%

|

≥350

|

|

Tensile Modulus

|

ASTMD 4321-2004

|

50mm/min

|

Mpa

|

≥150

|

|

Heat sealing strength

|

ASTM F88-06

|

300mm/min

|

N/15 mm

|

≥8

|

|

Right angle tear strength

|

ASTM D1004-2009

|

500mm/min

|

N/mm

|

≥90

|

|

Thermal

|

|

Heat Distortion Temp.

|

ASTM D648-2007

|

1.8Mpa

|

°C

|

<100

|

|

Others

|

|

|

|

|

|

Melt Flow Rate

|

ASTM D1238-2010

|

190°C, 2.19K

|

g/10min

|

2-5

|

|

Density

|

ASTM D792-2007

|

23°C

|

g/cm3

|

1.30±0.05

|

|

Biodegradation

|

|

biogradation rate in 12 weeks

|

EN 13432

/ASTMD 6400

|

|

%

|

>98

|

Note:

1. Do not need to pre dry, open the package can be used directly. If the product moisture exceeds the standard, it should be used after drying treatment, drying time 4 h, temperature 80°C.

2. The data for tensile strength and breaking elongation refer to the finished film product.

Deutsch

Deutsch русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의

SUPPORT 24/7

SUPPORT 24/7 BUSINESS QUIRY

BUSINESS QUIRY Our ADDRESS

Our ADDRESS  Leave A Message

Leave A Message

IPv6 network supported

IPv6 network supported